Wastewater treatment plants are large non-linear systems subject to large perturbations in flow and load, together with uncertainties concerning the composition of the incoming wastewater. Nevertheless these plants have to be operated continuously, meeting stricter and stricter regulations.

Many control strategies have been proposed in the literature but their evaluation and comparison, either practical or based on simulation is difficult. This is partly due to the variability of the influent, to the complexity of the biological and biochemical phenomena and to the large range of time constants (from a few minutes to several days) but also to the lack of standard evaluation criteria (among other things, due to region specific effluent requirements and cost levels).

It is difficult to judge the particular influence of the applied control strategy on the reported performance increase, as the reference situation is often most suboptimal. Due to the complexity of the systems it takes much effort to develop alternative controller approaches, so that seldom a fair comparison between different options is made. And even if this is done, it remains difficult to conclude to what extent the solution is process or location specific.

To enhance the acceptance of innovative control strategies the evaluation should be based on a rigorous methodology including a simulation model, plant layout, controllers, performance criteria and test procedures.

Starting in 1998, several benchmark tools were developed for evaluating by simulation, control strategies for activated sludge plants. The benchmark development has being undertaken in Europe by Working Groups of COST Action 682 and 624, and later under the umbrella of an IWA Task Group.

The benchmark is a simulation environment defining a plant layout, a simulation model, influent loads, test procedures and evaluation criteria. For each of these items, compromises were pursued to combine plainness with realism and accepted standards. Once the user has validated the simulation code, any control strategy can be applied and the performance can be evaluated according to certain criteria.

Three benchmarks have been developed:

BSM1: relatively simple, it combines nitrification with predenitrification, which is most commonly used for nitrogen removal. The control strategies are evaluated over periods of 14 days, with different weather conditions.

BSM1LT: it is based on BSM1, but with a longer evaluation period (609 days). Faults (toxic events, problems on sensors and actuators) can occur.

BSM2: The BSM2 layout includes BSM1 for the biological treatment of the wastewater.The sludge treatment is taken into account.

BSM1

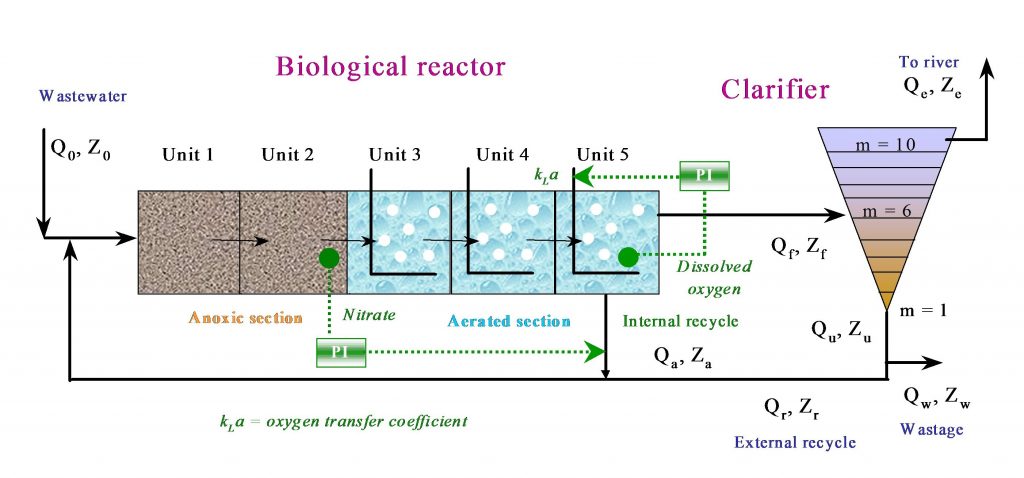

The BSM1 is composed of a five-compartment reactor with an anoxic zone and a secondary settler. A basic control strategy is proposed to test the benchmark: its aim is to control the dissolved oxygen level in the final compartment of the reactor by manipulation of the oxygen transfer coefficient, and to control the nitrate level in the last anoxic compartment by manipulation of the internal recycle flowrate.

The full description is available as a pdf file. The three weather files (dry, rainy and stormy weathers as well as the noise files are downloadable below.

ATTENTION: the data files have the full set of variables (i.e time, 13 ASM1 state variables, flowrate):

t Si Ss Xi Xs Xbh Xba Xp So Sno Snh Snd Xnd Salk Q

BSM2

The BSM2 layout includes the BSM1 for the biological treatment of the wastewater and the sludge treatment. A primary settler, a thickener for the sludge wasted from the BSM1 clarifier, a digester for treatment of the solids wasted from the primary clarifier and the thickened secondary sludge as well as a dewatering unit have been also added. The liquids collected in the thickening and dewatering steps are recycled ahead of the primary settler.

A full description of BSM2 is available as a pdf file. The data file is available as a compressed file.

An important part of the development of BSM2 has been to implement the ADM1 model for the anaerobic digester. This has implied some slight changes with respect to the original version of ADM1 as well as the development of calculation procedures in order to have a reasonable calculation time for the whole BSM2 plant. A report is available to describe the implementation of ADM1 within the framework of BSM2. Furthermore the MATLAB files are available on request. Contact Prof Ulf Jeppsson (ulf.jeppsson@iea.lth.se) when you need them.

Risk module

Many phenomena that cause operational problems in WWTPs are of qualitative nature. Some of them are caused by imbalances of microorganisms (filamentous bulking sludge, filamentous foaming or deflocculation) while some are caused by undesirable operating conditions (rising sludge). Currently these problems cannot be considered in the Benchmark Simulation Models (BSMs), which are based on control algorithms and numerical models.

The inclusion of an add-on risk module to the BSMs based on qualitative aspects provides a ‘third dimension’ for the evaluation of control strategies, i.e. operational costs, effluent quality and operational risks, and thus overall more realistic results can be provided.

This module has been proposed by colleagues from LEQUIA (University of Girona) and IEA-LTH (Lund University).

For more reading: X. Flores-Alsina, J. Comas, I. Rodriguez-Roda, K.V. Gernaey, C. Rosen (2009) Including the effects of filamentous bulking sludge during the simulation of wastewater treatment plants using a risk assessment model, Water Research, 43, 4527-4538. DOI: 10.1016/j.watres.2009.07.033